Meat

Application in meat industry

Fresh Meat

In the self-service sector, customers assess product quality based on color and presentation. Whether it’s portioned meat, minced meat, or large primary cuts, an appealing package plays a crucial role in purchasing decisions.

At IHS+, we are committed to delivering high-quality, reliable, and efficient processing and packaging solutions. Our advanced film packs tightly conform to the shape and texture of your fresh meat, ensuring an attractive display without compromising quality or weight. Additionally, IHS+ skin packs offer superior product protection and visual appeal, enhancing consumer confidence in the selfservice market. Even meat cuts with pointed bones or frozen products can be securely packaged with our puncture-resistant solutions.

With our comprehensive customer support, we assist you throughout the entire lifecycle of your packaging line. Our integrated portioning solutions from TVI ensure that your meat products are presented attractively while minimizing waste and reducing giveaway.

Backed by decades of industry experience and close collaboration with our customers, we understand the demanding requirements of the meat industry. Our expert team provides tailored guidance to help you achieve optimal processing and packaging solutions for your business.

Poultry

IHS+ is a trusted provider of end-to-end packaging solutions for the poultry sector, offering a seamless process from product handling and loading to final crate packing and palletizing.

Our diverse range of packaging systems ensures optimal protection, presentation, and efficiency for poultry products. We provide innovative solutions across five key packaging technologies: Shrink Film, Horizontal Flow Pack (HFFS), Thermoforming, Tray Sealing, and Vertical Flow Pack (VFFS).

With our expertise and commitment to quality, IHS+ delivers reliable and high-performance packaging solutions tailored to meet the unique demands of the poultry industry.

Process Meat

IHS+ is a professional supplier of packaging solutions for the processed meat industry, covering a wide range of products such as frankfurters, sausages, luncheon meat, bacon, and processed chicken nuggets. Unlike fresh meat, the red color of processed beef products is preserved through the addition of specialized ingredients like salt, spices, and sodium nitrite during processing.

To ensure product quality and longevity, processed meat packaging must effectively prevent oxygen absorption and water loss while maximizing shelf life. This is essential for maintaining freshness throughout extended distribution chains and accommodating consumers’ irregular purchasing patterns.

As a result, processed meat is predominantly packaged using multilayer composite films, which support vacuum sealing and freezing. These high-performance films incorporate advanced barrier materials such as PVDC, EVOH, and nylon, offering superior protection and extended shelf life—making them the preferred choice for long-term preservation in the industry.

Beef Snack (Beef Jerky and Stick...)

At IHS+, we manufacture stand-up pouches, lay-flat pouches, and roll stock for meat snack of all sizes. Our team of flexible packaging experts will work with you to create a custom package to fit your needs, or you can choose from our standard pouch sizes. Some of the many features available for beaf snack packaging include resealable zippers, optional hang holes and custom shaped pouches.

Types of Meat Packaging Materials We Supply

Coextruded Thermoforming Film (IHS+Form)

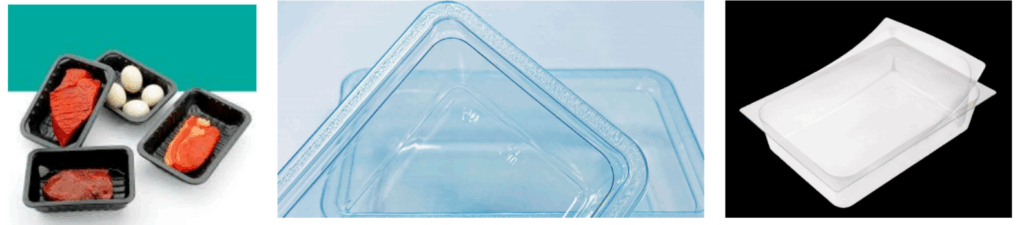

IHS+ coextruded thermoforming films(IHS+Form) are designed to meet the diverse needs of the meat packaging industry, offering both barrier and non-barrier options for fresh and frozen meat applications.

Key Features:

Superior Color Retention – Prevents fading to maintain product freshness and visual appeal.

Exceptional Sealing Performance – Ensures a secure, reliable seal for optimal product protection.

Outstanding Machineability – Designed for high-speed production with minimal downtime.

High Puncture Resistance – Protects against leaks and external damage, ensuring product integrity.

Crystal Clear or Pigmented Options – Provides flexibility for enhanced retail presentation.

Anti-Fog Technology – Maintains a clear, attractive display even in high-moisture environments.

IHS+ Easy-Tear Technology – Enables a clean, effortless opening for improved consumer convenience.

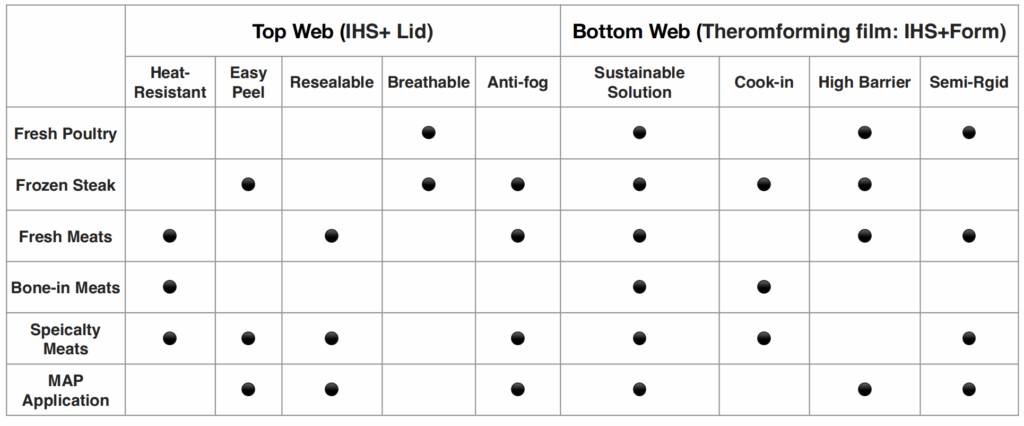

Overview our IHS+ Theromforming Top and Bottom Web Application:

Shrink Rollstock and Bag

IHS+ Shrink Rollstock Film

Our IHS+ shrink rollstock film is designed to optimize efficiency in meat packaging, reducing labor requirements by up to 60% by minimizing manual

steps in the packaging process.

Key Features:

Versatile Compatibility – Suitable for use with flow wrap and thermoforming equipment for seamless integration.

Premium Visual Appeal – Delivers exceptional optical clarity and supports high-end flexographic registered printing for enhanced branding.

Multiple Thickness Options – Available in various thicknesses to provide superior protection, even for high-abuse products.

Extended Shelf Life – Offers multiple barrier options to maximize product freshness and protection.

High Shrink Performance – Reduces excess material in corners and minimizes product purge, ensuring a clean, tight package.

IHS+ Shrink Bags

Our IHS+ shrink bags provide superior protection for bone-in and boneless fresh beef throughout distribution while maintaining an attractive retail presentation.

Key Features:

Reliable Conformity – Premade shrink bags that tightly conform to the product shape for optimal fit and protection.

High Shrink Efficiency – Minimizes excess material in corners, reducing product purge and enhancing presentation.

Exceptional Barrier Properties – Extends product shelf life by ensuring maximum freshness and protection.

Enhanced Product Visibility – Designed to showcase the natural quality of your meat products at retail.

Sustainable Shrink Rollstock and Bag

The IHS+ Sustainable Shrink Rollstock and Bags are engineered with mono-material polyethylene (PE) for enhanced recyclability. When clean and dry, these films can be recycled through store drop-off programs or curbside collection, where available, supporting a circular economy in flexible packaging.

Key Features:

Designed for Recycling – Made from mono PE, ensuring compatibility with existing recycling streams.

Versatile Production Compatibility – Runs efficiently on HFFS (Horizontal Form-Fill-Seal) and thermoforming production lines.

Effortless Opening – Can be paired with easy-peel technology for enhanced consumer convenience.

Barrier & Non-Barrier Options – Available in both formats to meet varied product protection needs.

Seamless Integration – Fully compatible with IHS+ non-forming materials for a complete, sustainable packaging solution.

Frozen Pouch/Bag

Our frozen pouch packaging solutions are designed to offer exceptional versatility in shape, size, format, and convenience features, ensuring an optimal experience for both brands and consumers.

Key Features:

Barrier & Non-Barrier Options: Available in both high-barrier and standard film structures to meet diverse product protection needs.

Flexible Formats: Offered as pre-made pouches or rollstock to accommodate various production requirements.

Film Variations: Available in clear, opaque, metallized, and other specialized finishes to enhance product presentation.

Premium Print Finishes: Choose from matte, tactile, satin, high-gloss, and other visually striking options to elevate brand impact.

Custom Shaped Pouches: Distinctive designs to enhance brand differentiation and consumer appeal.

Consumer Convenience Features: Includes easy-open directional tear, resealable options (press-to-close zippers, sliders, etc.), peel-off coupons, promotional features, and carrying handles for added portability.

Wicketing Options: Designed for seamless integration with high-speed packaging operations.

Diverse Packaging Formats: Available in stand-up pouches, side-seal pouches, vertical pillow packs, fin/lap seal configurations, and more.

Our high-definition graphics and premium finishing options maximize shelf appeal, while flexible design choices help create a distinctive brand presence. Lightweight, portable, and user-friendly, our frozen pouch solutions deliver superior usability with easy-open, resealable, and promotional features for a seamless consumer experience.

Chub Films for Ground Beef and Casings

Ensure superior protection and performance for your fresh and frozen beef products with IHS+ chub films, available in both barrier and non-barrier options to meet diverse packaging needs.

Key Features:

Suitable for 1, 2, 3, 5, 10, and 20-pound applications.

Available in plain or printed formats for customized branding.

High graphic durability with reverse print, durable surface inks, and protective overlacquers.

Offered in clear or white pigmented film options to enhance product visibility and appeal.

Superior machinability – Features excellent slip properties and a wide sealing window for efficient, high-speed processing.

Longer Shelf Life: Ground beef packaged in chubs can improve a shelf life of up to 45 days which is longer than when packaged in trays.

High Strength and Tear Resistant: Built-in durability to withstand more handling during a longer time in storage

Retort Meat Pouch&Bags

IHS+ provides premium food-grade and microwavable packaging materials, exceeding industry standards. Beyond the typical PET/Al Foil/Nylon/Retortable CPP structures, we offer transparent and custom-printed retort bags made from high-barrier materials to ensure superior product protection and quality. Our packaging solutions withstand high temperatures of up to 121°C / 135°C and are FDA & BRC approved, making them ideal for a wide range of food applications, including ready-to-eat meals, sauces, soups, and pet foods. Designed for consumer convenience, these pouches are lightweight, easy to store, transport, and open.

Our microwavable retort vacuum bags utilize a multi-layer, metal-free laminated film structure that provides excellent barrier protection against moisture, oxygen, and light, ensuring product freshness and extended shelf life. A common material composition includes PET/Nylon/Retortable CPP. Additionally, retort pouches offer a sustainable alternative to traditional metal cans and glass jars by reducing packaging weight and environmental impact.

Easy Peel and Resealable Packaging

Enhance consumer convenience with easy-open, resealable packaging, while optimizing costs and sustainability. Our innovative solutions improve product freshness, reduce food waste, and streamline packaging efficiency.

Key Features:

Compatible with flexible and rigid applications

Available in resealable pre-made pouches and stand-up pouches

Designed for HFFS (Horizontal Form-Fill-Seal) systems

Customer Benefits:

Superior Functionality & Freshness – Provides the easy-open, resealable convenience consumers expect.

Extended Shelf Life & Waste Reduction – Helps preserve product quality and minimize food waste.

Cost & Sustainability Advantages – Reduces material usage and transportation costs, benefiting both the environment and your bottom line.

Reliable Reclosability – Offers a more user-friendly alternative to sliders and zippers.

Source Reduction – Eliminates the need for additional rigid tray and lid components, simplifying packaging.

Integrated Printing Capabilities – Printable lidding removes the need for separate labels, reducing extra materials.

Tamper-Evident Safety – Provides consumer confidence with built-in security features.

Knife-Free Opening – Eliminates the need for scissors or knives, ensuring a safe and effortless experience.

Anti-Fog and Anti-Grease Films

Enhance product visibility and shelf appeal with IHS+ Anti-Fog and Anti-Grease Films, designed to maintain a crystal-clear product view by effectively managing fogging, moisture, and oil buildup.

Key Features:

Suitable for flexible, semi-rigid, and rigid film applications

Compatible with existing packaging equipment for seamless integration

Customer Benefits:

Clean & Attractive Retail Presentation – Ensures a clear, professional display, enhancing product appeal.

Effortless Transition – Runs on standard packaging equipment like conventional films, minimizing process adjustments.

End Consumer Benefits:

Crystal-Clear Product Visibility – Allows consumers to see the quality and freshness of the product inside.

Enhanced Shelf Appeal – Creates a more inviting and premium retail presentation, driving purchase decisions.

Tray and Lids

IHS+ rigid thermoformed trays provide a versatile packaging solution, offering a wide range of materials, barrier levels, and shapes to meet diverse product and cooking requirements.

Key Features:

Available in multiple material options, including CPET, APET, and PP, tailored to specific applications.

Offered in various thicknesses, barrier levels, and custom shapes to ensure optimal protection and presentation.

Color options include clear, natural, white, black, with additional choices available upon request.

Custom design capabilities to meet unique branding and product needs.

Multiple sealant options enhance shelf life and retail appeal, including:

PE, metallocene, ionomer, antifog, and easy-peel technologies.

Available with post-consumer recycled (PCR) content, supporting sustainable packaging initiatives.

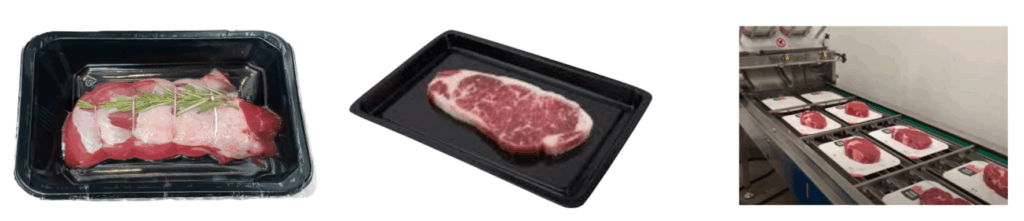

Vacuum Skin Packaging

Vacuum Skin Packaging (VSP) offers superior value for both processors and retailers compared to traditional case-ready packaging. By providing an extended fresh shelf life and minimizing meat purge, VSP enables wider distribution and enhanced product integrity. Retailers benefit from longer display life (25–30 days vs. 3–5 days) and significantly reduced product loss (<5% vs. 10%), ensuring greater profitability. The tight, form-fitting package also enhances product presentation, keeping food securely in place for an appealing retail display.

Key Features & Benefits:

Available in multiple thicknesses to suit various product needs.

Versatile compatibility – Can be used with rollstock or pre-formed trays.

Wide range of sealing materials, including PE, PP, PET, and ALU, for diverse applications.

High-performance materials allow for down-gauging, reducing material usage compared to competing skin packaging solutions.

Seamless functionality across all VSP machines and applications, including super protrusion and sharp-edged products.

Matte finish option available for a premium, differentiated presentation.

Customizable surface printing – Supports up to 10 colors for enhanced branding and visibility.

MAP Packaging (Modified Atmosphere Packaging)

IHS+ Modified Atmosphere Packaging (MAP) sets a new benchmark for freshness and shelf-life extension in premium and specialty baked goods. As a superior alternative to traditional cold chain packaging, this advanced technology empowers processors and retailers to expand distribution without compromising product quality during transit.

Our IHS+ MAP solutions, including high-performance lid films, overwrap films, and thermoforming films, effectively preserve the freshness of baked goods for an extended period. To ensure optimal barrier protection against gas exchange, MAP films are engineered with multiple layers of specialized materials. Since no single material can fulfill all functional requirements, these films are composed of coextruded or laminated polymeric structures, each selected to meet specific packaging needs. This multilayer design guarantees superior atmospheric control, enhancing product integrity and extending shelf life based on individual customer specifications.

Customized Packaging Machinery Solutions