Coffee

As a full-range coffee packaging value supplier, we deliver comprehensive, end-to-end solutions designed to meet the diverse needs of the global coffee market. Our packaging options cater to whole bean, ground coffee, and instant coffee products, ensuring freshness, quality, and shelf appeal.

Coffee Market Needs

Whole Bean Coffee

Whole beans are typically packaged using multi-layer composite films combined with a one-way degassing valve. This structure prevents oxygen and moisture intrusion while allowing carbon dioxide produced during roasting to escape, preserving freshness. Many packages feature resealable closures for added convenience and extended storage.

Ground Coffee

Ground coffee, being more sensitive to oxygen and moisture, requires enhanced protection. Multi-layer films with degassing valves or aluminum foil vacuum packaging are commonly used. Vacuum-sealed bags isolate air and moisture, maintaining the aroma and flavor of specialty ground coffee.

Instant Coffee

Instant coffee is often packaged in stick packs or sachets, offering single-serve portions that are lightweight, easy to carry, and convenient for quick preparation.

Types of Coffee Packaging

Choosing the right packaging solution enhances product protection, brand presentation, and customer experience. We offer a wide variety of film-based coffee packaging formats, including:

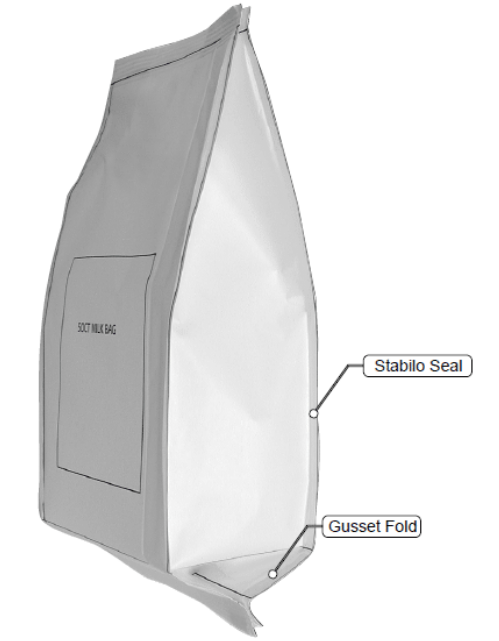

Pre-Made Flat Bottom Bags / Stabilo® Bags

A popular choice among specialty coffee brands in Europe and North America, Stabilo bags offer superior aesthetics with a box-like structure and five printable panels (front, back, sides, and bottom). They feature self-sealing zippers, degassing valves, and stand upright on shelves.

Quad Seal Bags / Stabilo Bags

Quad Seal bags enhance stability with four vertical seals, resembling traditional paperboard cartons. They are ideal for specialty coffee packaging, offering superior branding opportunities and a premium shelf presence.

Gusseted Bags / Flat Bottom Bags

Produced using vertical form-fill-seal (VFFS) machines, gusseted bags are formed from roll stock film. These bags are economical, adjustable for different capacities, and provide excellent shelf display. Optional four-edge hot pressing adds a more structured, three-dimensional shape.

Stick Packs

Designed for single-serve instant coffee, stick packs are portable, lightweight, and provide precise portion control, making them perfect for on-the-go consumers.

Sachets

Sachets are commonly used for steeped or drip coffee applications. They are typically sealed on three or four sides and act as outer packaging for individual coffee servings.

Vacuum Brick Bags

Vacuum brick bags, often made from aluminum foil film, provide high-barrier protection against moisture and oxygen. They are ideal for products requiring long shelf life and are formed through processes including vibration, pressing, vacuuming, and sealing, resulting in a compact brick-like shape.

Stand-up pouches provide a cost-effective alternative to rigid containers, with excellent shelf stability, resealable closures, nitrogen flushing options, vacuum sealing, and one-way valve integration to ensure coffee freshness.

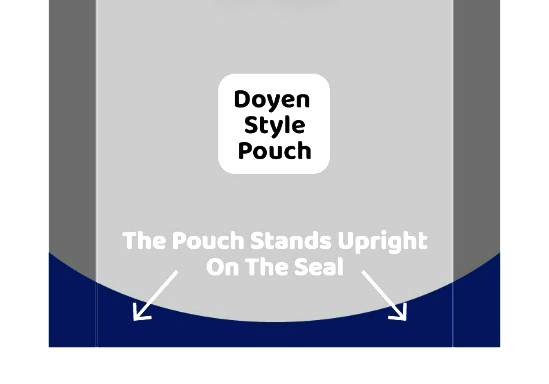

Doyen Bottom Pouch (also known as Round Bottom Gusset Pouch or Doypack)

The Doyen bottom pouch is the most common style among stand-up pouches in the market. Characterized by a U-shaped gusset and round bottom with corner-sealed edges, it allows the pouch to stand upright on shelves. In this design, the product’s weight is supported by the bottom seal, making it ideal for lightweight items (typically less than 1 pound or 0.45 kg).

Due to its structure, heavier products may compromise the pouch’s appearance by causing the bottom seal to collapse. Standard Doyen pouches are usually smaller in size. Producing this style generally requires a custom die, adding a slight additional manufacturing cost. However, the Doyen pouch is particularly suitable for showcasing smaller amounts of product while maintaining a shorter overall height.

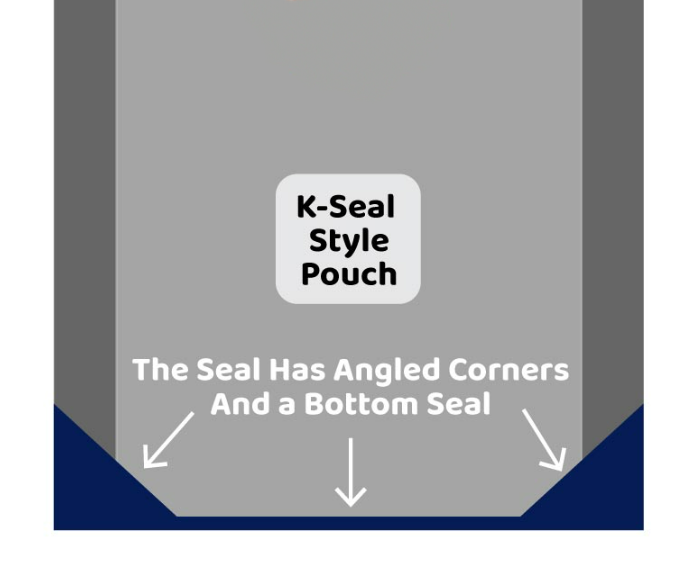

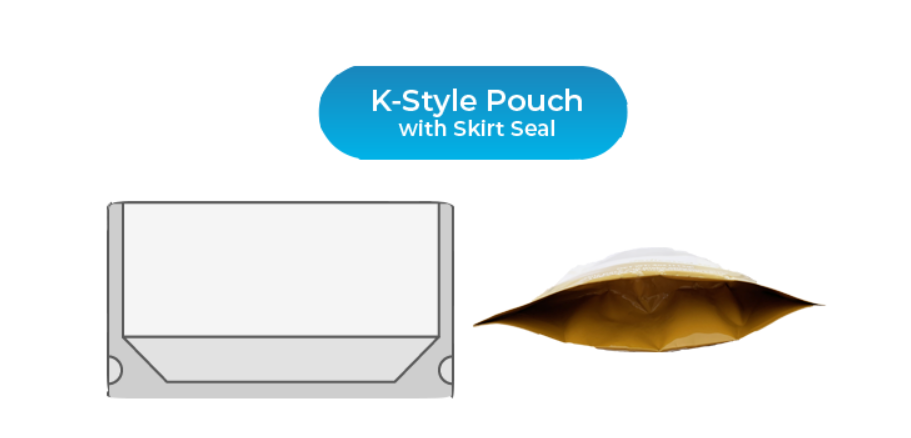

K-Seal Bottom Pouch

As demand for greater capacity and heavier product packaging increases, the K-Seal bottom pouch becomes the preferred choice for products weighing between 1 to 5 pounds (0.45–2.25 kg).

The K-shaped seals at the bottom of the pouch provide greater strength and stability, allowing it to hold heavier products without compromising the pouch’s appearance or ability to stand upright. Unlike the Doyen style, K-Seal pouches typically do not require a custom die for production. In our experience, the K-Seal pouch expands less at the bottom, so for the same product volume, it may require a slightly taller pouch compared to a Doyen pouch. This type is especially suitable for powders and granular products.

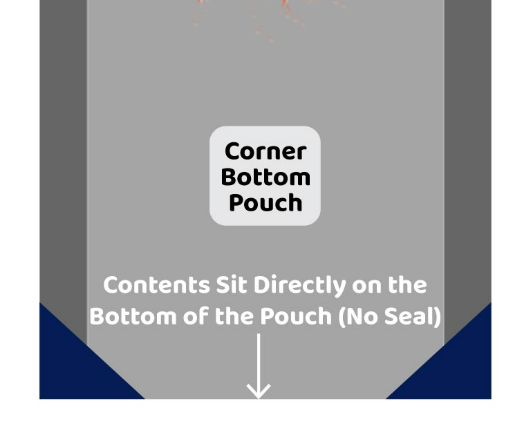

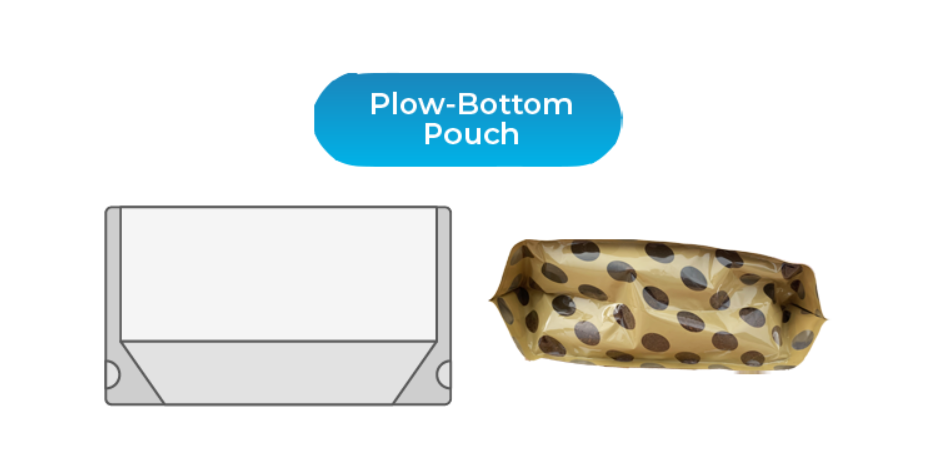

Plow Bottom Pouch (also known as Corner Bottom or Folded Bottom Pouch)

Also referred to as the Corner Bottom or Folded Bottom pouch, the Plow Bottom pouch is highly recommended for packaging products weighing over 5 pounds (2.3 kg and above).

In this design, the bottom is folded rather than sealed, allowing the product to sit flat directly on the base of the pouch. The side seals provide structure, while the product’s weight naturally supports the pouch’s upright position without the need for a bottom seal. This pouch style has gained significant popularity in the food industry for packaging granular products such as salt, sugar, and similar items.

Although designed for heavier items, Plow Bottom pouches are versatile—lighter products can also use this style effectively. For instance, an 8 oz (227 g) bag of cranberries may successfully be packaged in a Plow Bottom pouch, demonstrating its adaptability.

Global Trends in Coffee Packaging

Personalization

Brands are embracing unique design elements—such as custom colors, matte/gloss combinations, foil stamping, and transparent windows—to create memorable, small-batch packaging with space for handwritten personalization by baristas.

Small Lot Packaging

Driven by the specialty coffee culture, smaller lot sizes (100–200g) highlight unique flavor profiles from specific micro-lots, appealing to connoisseurs seeking distinct experiences.

Tactile Surfaces

Engaging multiple senses, soft-touch finishes, and textured coatings create a premium, tactile experience for consumers.

Sustainability

Growing consumer awareness is pushing brands toward recyclable, biodegradable, and eco-friendly packaging innovations, aligning with global efforts toward a greener future.

Materials Used in Coffee Packaging

Preserving coffee’s flavor, aroma, and freshness is crucial. We offer packaging materials that ensure product integrity:

Ensuring Coffee Freshness and Aroma

Our packaging solutions are engineered to lock in coffee’s freshness through:

Light-Proof Sealing: Multi-layer films with aluminum lining protect against light, oxygen, and moisture.

Vacuum Packaging: Eliminates air exposure, ideal for ground and whole bean coffee.

One-Way Degassing Valves: Allows carbon dioxide to escape without letting oxygen enter, preserving the roasted coffee’s integrity..

Nitrogen Flushing: Replaces oxygen within the bag, preventing oxidation.

Resealable Closures: Enables consumers to maintain product freshness after opening.

Desiccant Inserts: Optional moisture and oxygen absorbers to extend product shelf life

Sustainable Coffee Packaging Solutions

Sustainability is at the heart of modern coffee packaging trends. We offer eco-conscious options to help brands reduce environmental impact:

Customized can packaging goes a step further by inspiring consumers to retain and reuse the packaging, turning it into a keepsake. This not only enhances brand visibility but reinforces long-term consumer loyalty. By encouraging consumers to retain, reuse, and emotionally connect with the packaging, brands not only extend their presence into daily life but also build deeper, more enduring relationships with their customers.